|

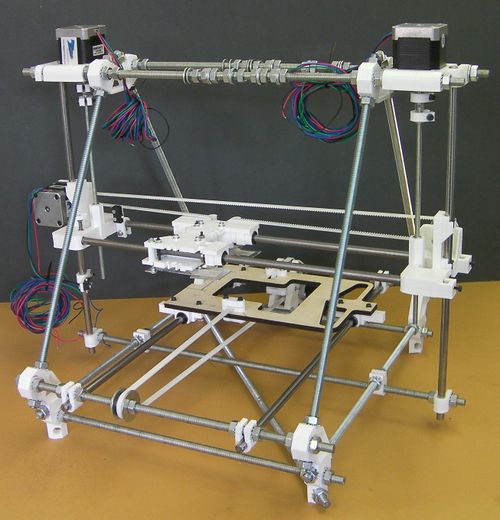

| Prusa Mendel printer (from www.reprap.org) |

Ive finally got round to a "deep clean" of my office, including the dozen or so boxes of old computer bits and various forgotten about projects.

One of those projects was a 3D repstrap printer which I probably got about half way through. A quick google shows that things have really come on a lot so I think its time to resurrect this project and finish it off.

3D printers consist of various blocks that are almost plug and play (think of it as object orientated hardware)

There is the main board, the CPU of the system and associated stepper motor drivers, heating element drivers, switch sensors etc.

There is the physical hardware that hold three stepper motors at ninety degrees to each other and move a carriage across the printing plane.

There is the print head, usually a heating element and a "pump" that forces a plastic into the heated chamber and out of a small nozzle. The printhead (extruder) has a thermistor that measures the temperature accurately.

Of course, this is a vastly simplified version of events!

I had bought and assembled several bits of electronics, namely a sanguino board (similar to an arduino), and three stepper motor drivers.

When I plugged everything together and tried to run a program, one of the stepper motors wasn't turning. This turned out to be a burnt out L297 chip which these boards were prone to. My choice is to replace the chip and carry on, or just buy a complete set of electronics for a new set up. In any case to get my current printer working will need me to buy another stepper motor driver (for the extruder printhead) and an extruder assembly.

Im going to opt for a complete set of electronics which will work out far cheaper in the long run. The old style of electronics were expensive and things have mover on considerably. You can now buy a microstepping stepper motor driver for £10 and a full set of electronics for £120

Initially, you create a "repstrap" printer which is a working printer that has some components bodged together using various bits of hardware. You then get the repstrap to print a replacement set of components and then rebuild the whole printer using replicated components.

Should keep me busy through the Summer!

Building your own from scratch, then having it rebuild itself is probably quicker than building one of these monsters ;-)

ReplyDeletehttp://www.eevblog.com/2012/02/23/eevblog-246-makerbot-thing-o-matic-time-lapse-build/

Yep, you are right. Some of the earlier monsters were just ore fiddly - the Makerbot is good though - whats the print quality like?

Delete